Unpiggable Solutions

Unpiggable Pipelines

If you have an unpiggable pipeline, you’ve come to the right place.

Fiberbuilt engineers pigs for the most demanding pipelines, such as extreme diameter changes, plus extreme heat, chemical, and product environments.

If you are having difficulty pigging a pipeline, we are here to help. Even if we aren’t your first call, we’re confident we can be your last.

Contact Fiberbuilt today to discuss solutions you may not have thought possible.

Even unpiggable pipelines can be inspected with Fiberbuilt IMU Pigs. Gather essential pipeline movement and bending strain data for pipelines that cannot be economically inspected with conventional ILI solutions. Fiberbuilt single-body IMU Pigs are low-cost, exceptionally simple, and easy to run.

FIBERBUILT UNPIGGABLE SOLUTIONS

Do you have a challenging pipeline? Call us for an engineered pigging solution.

Extreme Environment Pigs

Extreme temperatures and harsh chemical conditions in pipelines can destroy standard cleaning pigs and make these lines unpiggable.

If not armed with engineered materials and modifications, these pigs may become stuck, broken, melt, or even disintegrate within the pipeline.

Fiberbuilt Extreme Environment Pigs are engineered to endure long-term exposure to unforgiving internal conditions, such as:

- Extreme high temperatures

- Steam

- Harsh chemicals

- Products in the pipeline

Highlight

Fiberbuilt Ultra-High Temperature Pig

Successfully operates in temperatures up to 650 F.

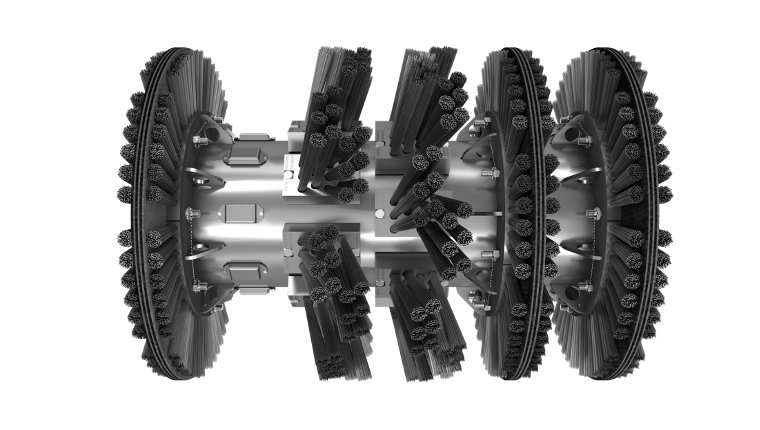

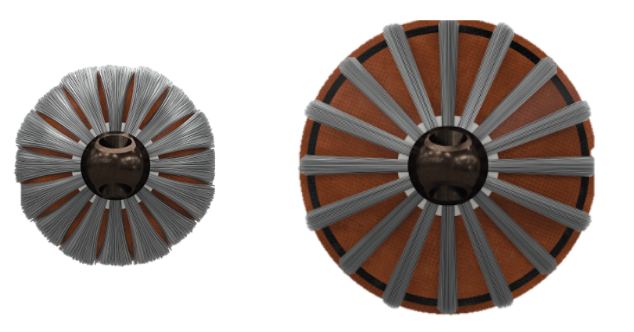

Multi-Diameter Pigs

Pigging smaller diameter multi-diameter pipelines is a significant challenge for pipeline operators. Often, diameter changes in small-diameter pipelines make them unpiggable.”

Fiberbuilt’s multi-diameter pigs are built to effectively pig the challenging small, multi-diameter pipelines.

These pigs feature a patented, flexible composite seal technology. This seal can reduce its OD by 50% in small-diameter pipelines 3″ and up.

Do you have a difficult-to-pig or even “unpiggable” pipeline? Fiberbuilt’s IMU pig is low-cost, simple, and easy to run, even through diameter changes, aggressive bends, complex geometries, and debris. Measuring bending strain and pipeline movement allows operators to proactively monitor pipelines. Learn about our IMU inspection mapping services here.

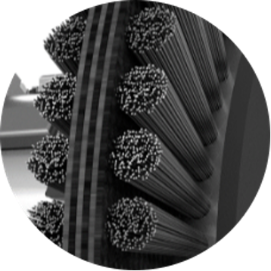

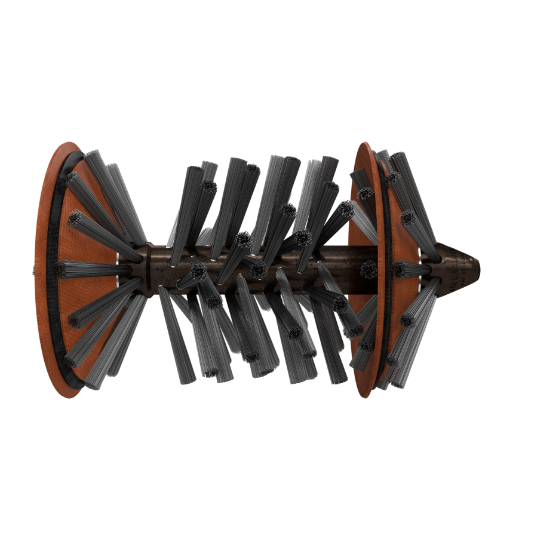

Corrosion Pit Cleaning Pigs

According to the Pipeline Hazardous Materials Safety Administration (PHMSA), internal corrosion is a leading cause of pipeline incidents, accounting for about 60% of total corrosion cases in pipelines. Corrosion pitting is one of the most dangerous forms of corrosion and significantly compromises pipeline integrity.

Pipeline operators try to address the cleaning of corrosion pits with brush pigs. However, brush pigs sweep over pits and do not reach the bottom of corrosion pits.

Fiberbuilt Patented Corrosion Pit Pigs are for deep corrosion pit cleaning.

Fiberbuilt Pit Cleaning Pigs have patented technology to yield maximum cleaning performance in corrosion pits.

- Forward-reaching spring steel wires dig deep into corrosion pits

- Removes 80% more volume from corrosion pits than a conventional brush pig

Review this video to observe how Fiberbuilt Corrosion Pit Cleaning Pigs penetrate deep into corrosion pits.

Let’s Get Started

Have a problem? Let’s discuss a solution.

Contact Fiberbuilt today.